roughing end mill depth of cut

The distance between scallops is referred to as pitch. From memory they are about 20mm 0800 and 10mm 38 with a plain spiral-fluted end mill - about 12mm 12 for scale.

7 Tips For Choosing The Right End Mill For The Job M M Sales Equipment

Ad Precision End Mills for Your Machine Cutting Needs With Custom Diameter Length More.

. Change geometry - use an end mill with variable flute spacing or a small circular margin. Tuesday March 15 2022. HEM is a roughing technique that uses a lower Radial Depth of Cut RDOC and a higher Axial Depth of Cut ADOC.

Cobalt roughing end mills are designed to withstand heat and abrasion and can be run at higher production rates without sacrificing tool life. Depth of Cut Strategy for High Efficiency Milling HEM Pairing a light RDOC and heavy ADOC with high performance toolpaths is a machining strategy known as High Efficiency Milling or HEM. This means a 050-inch end mill will be engaged 0025 to 0050 inch.

For example the average recommended feed rate for a 050-inch tool is approximately 0002 inch per tooth. Made of solid carbide these end mills are harder stronger and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Machining to Zero with the Mold Meister Ball End Mill.

High Performance Milling SFM750 RPM9500 Feed 80 ipm End Mill R4 Mold Steel 53HRC R4 Radial Depth 4mm axial Depth025. Carbide can take more but staying with this guideline works for most of the end mills you will use. Standard depths of cuts for roughing end mills can be set at a larger value than ordinary type end mills.

Ad Inch and Metric Mills - Single or Double End Roughing Mini Long Ball End. Choose From Various Sizes Applications. End mill was average length with 15 LOC flute for 58 dia end mill.

Usually something like 2-3x chip load will be right for the finish pass. The cutting speed varies with the amount of radial depth of cut when profiling and axial depth of cut when slotting. 3 Flute Carbide Roughing End Mills CNC Machine Tool 50.

Stock Material Surface Speed. Carbide Four Flute End Mill HRC55 - 65 Micro Grain. The machining time spent roughing your workpiece is mostly determined by Material Removal Rate.

Radial Side Depth of Cut. Normally a 20 reduction in effective horsepower is used. With this machining style feed rates can be increased and cuts are kept uniform to evenly distribute stresses across the cutting portion of the tool prolonging tool life.

End Mill Speed Feed Calculator. Volumes of material can be removed at high cutting speed. Material removal rate MRR is high.

I was wondering what others normally consider maximum depth of cut ratio to diameter of end mill with a roughing end mill milling cast iron medium hardness. Roughing end mill depth of cut. Get Fast Reliable Shipping.

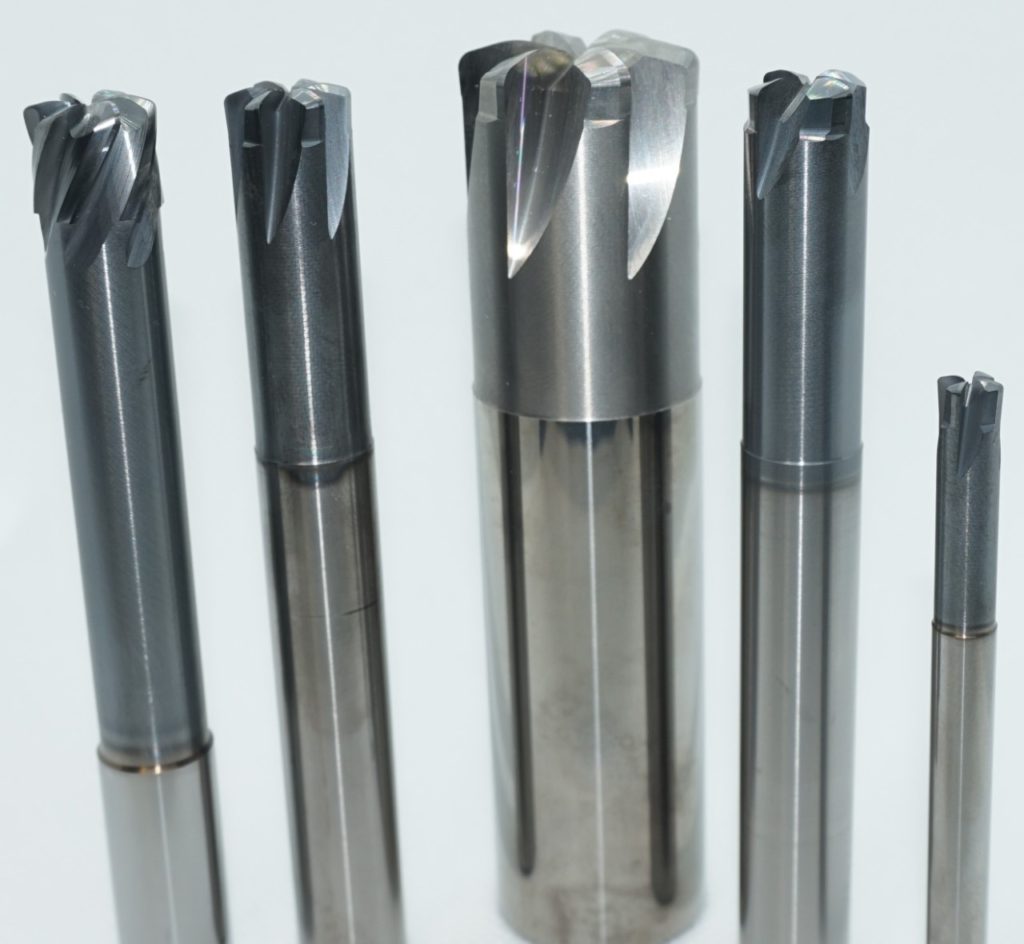

Roughing End Mills have scallops on the cutting edges which cause the chips to break into smaller segments. Objective of rough pass is to remove bulk amount of excess material from workpiece in every pass. The Secret Mechanics Of High Feed End Mills In The Loupe.

They are designed to remove large amounts of material quickly and more efficiently than standard end mills. The depth of cut has to be larger than the chip load or you can get rubbing. Higher feed rate and depth of cut are utilized.

This will adjust the feedrate if less than the tool rad. Also for the same reason the depth of cut for semi-finishing end mills can be increased. Carbide Square End Mills.

55 - 65 HRC CNC Cutting Tools Roughing End Mill With. Here are two of my roughers - aka Corncobs. Heavy cuts can be achieved because our roughing end mills have a much higher effective feed per tooth than a conventional end mill.

While traditional roughing is occasionally necessary or optimal it is generally inferior to High Efficiency Milling HEM. Regal Cutting Tools manufactures a variety of roughers for a wide range of materials and conditions. Roughing End Mill You Can Buy good quality Roughing End Mill of page 2- We are Roughing End Mill exporter Roughing End Mill manufacturer from China market.

For high-speed roughing width of cut is usually set at somewhere between 5 and 10 percent of the cutting tool diameter. This results in lower cutting pressures at a given radial depth of cut. Pre-Hardened Steels Mold Steels Hardened Steels H13 D2 M3 4560 Hrc -.

Volumes of material can be removed at high cutting speed. Now heres the last piece. Top-Quality End Mills for Your Machining Needs.

The deeper you go the slower you need to go. Their extreme hardness means they are brittle so a highly rigid setup such as a CNC machine is necessary to prevent the end mill from. MRR Axial Depth of Cut Radial Depth of Cut Feed Rate all values in inches or inches per minute for Feed Rate This formula yields the number of cubic inches per minute your cutting tool is removing.

The tooth design and flute construction minimizes deflection and maximizes chip ejection. Increase your systems rigidity by changing over to a stub length end mill or improving your workpiece fixturing. This setting will impact RCT calculations as well.

This spreads wear evenly across the cutting edge dissipates heat and reduces the chance of tool failure. Very low feed rate and depth of cut are utilized. Reduce your cutting forces by reducing speed andor feed or axial andor radial depth of cut.

They do cut very well - higher feed rates and depths and lengths of cuts - but over-loading or over-speeding will ruin them. One Pass Grinding from Ball Nose to Outer Tooth. Ad Search Graingers Online Catalog.

This is because the cutting resistance is reduced because the chips are broken into short lengths by the wavy cutting edges. Objective of finish pass is to improve surface finish dimensional accuracy and tolerance. This has to do with deflection of the end mill more than anything else.

Roughing End Mills - Cobalt and High Speed Steel. Cutting speeds also vary with the end. Normally i would use a depth of cut of 31 to 625 with a 625 dia roughing end mill for a full width slot feeding straight across G1.

Advanced Roughing Strategies Faster Through Optimized Toolpaths Secotools Com

Yonico 5 16 In Dia X 5 16 In Carbide 3 Flute Upcut Spiral End Mill Shank Solid Cnc Router Bit 31340 Sc

Multiple Uses Of Chamfers Multiple Cost Saving Canning

4 6 Flute High Feed End Mills Epic Tool

Selecting The Right Plastic Cutting End Mill In The Loupe

What To Know When Selecting An End Mill End Mill The Selection Machining Process

Hanzel 5 Things Should Know How To Selecting End Mill

Power Feed From Ingersoll Video In 2020 Cnc Machinist Cnc Programming Cnc Machine

End Mill An Overview Sciencedirect Topics

Endmill Selection Guide Redline Tools Redline Tools

End Mill Tool With High And Low Helical Flutes And Related Method For Rough Cutting And Finishing A Workpiece Destiny Tool

The Secret Mechanics Of High Feed End Mills In The Loupe

Tialn Coated M42 8 Cobalt Roughing End Mills Standard Tooth Accusize

Everything You Need To Know About Endmills Basic Beginners Guide Accusharp Endmills Accusharp Cutting Tools Accusharp

Speed Feed Recs Melin Tool Company

Vqt6ur Mitsubishi Materials Corporation

An In Depth Look At Helical S Tplus Coating For End Mills End Mill Multi Layering Solutions